Interested in working with us?

Quality Assurance

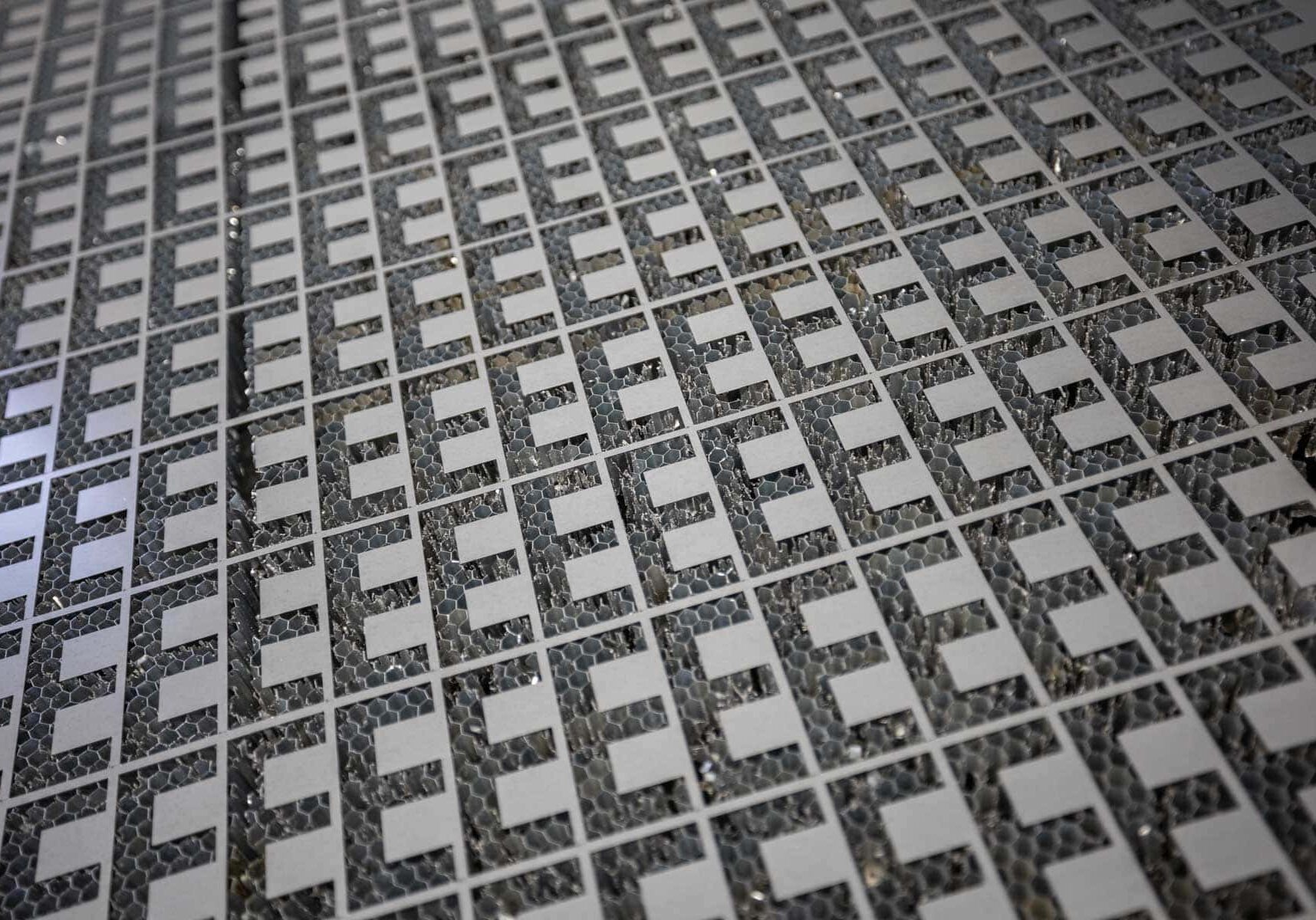

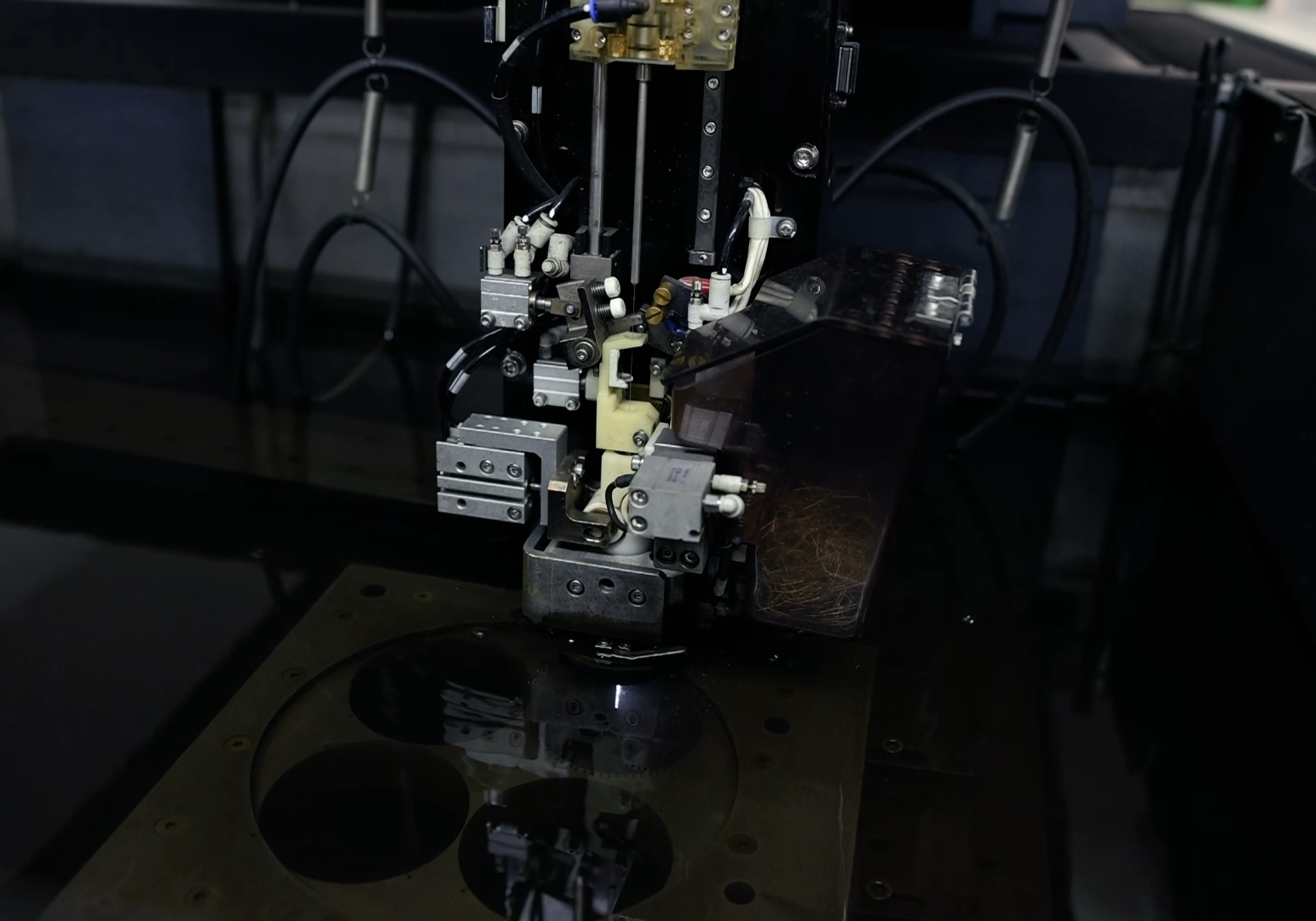

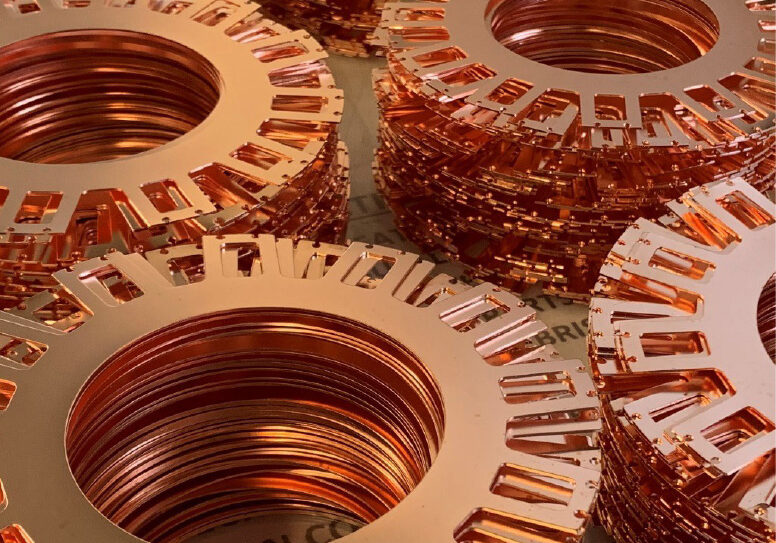

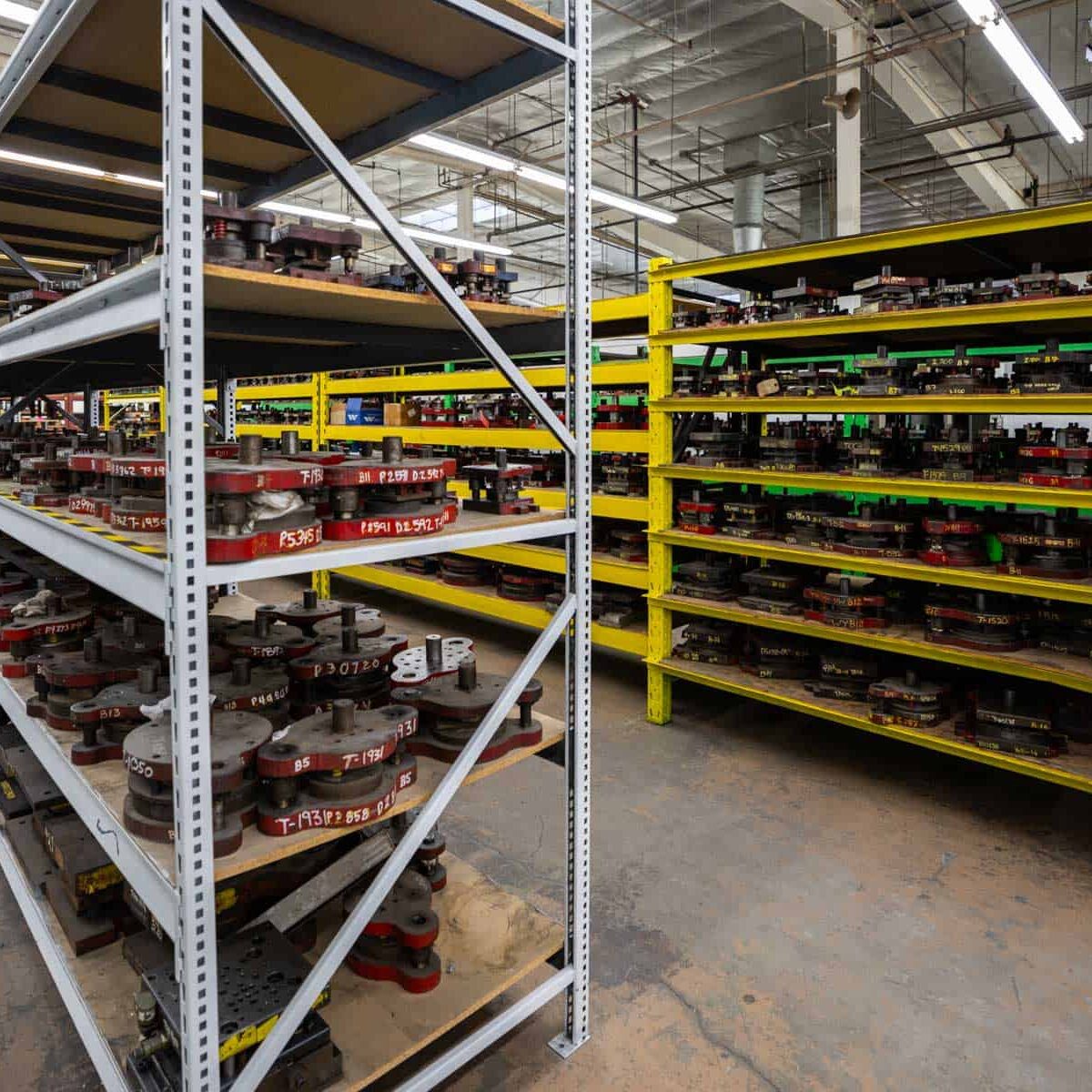

At Fred R. Rippy, Inc., our commitment to excellence isn't just a statement—it's an ingrained practice. Quality assurance forms the backbone of our services, ensuring that every product not only meets but often exceeds industry standards and client expectations.

Certified Excellence: Holding both AS9100 and ISO9001 certifications.

Comprehensive Monitoring: Rigorous quality checks at every production stage.

Trusted Suppliers: Collaborating only with approved suppliers for impeccable outcomes.

Continuous Improvement: Regularly updating processes and training for top-tier results.

Frequently Asked Questions

Fred R. Rippy, Inc. stands apart due to our seven-decade legacy, our relentless focus on quality, and our comprehensive in-house offerings. Being both AS9100 and ISO9001 certified, we serve the most demanding aerospace companies, ensuring unparalleled precision and personalized service.