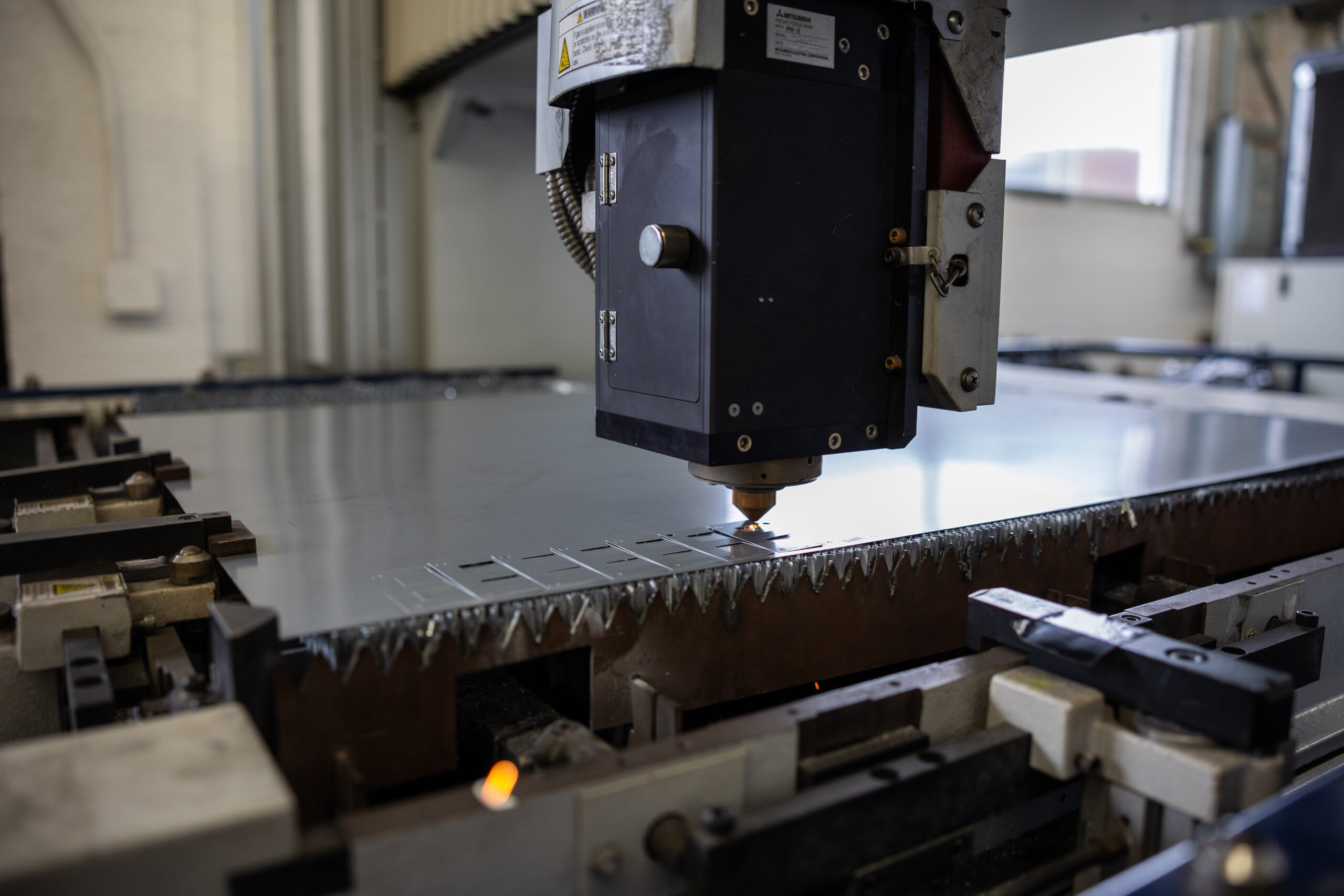

Laser Cut Laminations

Advanced Laser Technology

Fred R. Rippy Inc. uses our CO2 Mitsubishi laser to cut both metal and insulating laminations up to 47” diameter and 0.25” thick. Laser cutting is slower than stamping and not as precise but it saves the time and cost of making specialty tooling. This is a good solution for rapid turnaround projects or small run prototype jobs. And, the parts are still put through all our rigorous quality checks so we know they meet all your specifications.

Our CO2 laser technology is engineered for rapid turnarounds, enabling clients to adhere to stringent product development timelines without compromising on cost efficiency. Coupled with an exhaustive inventory of raw materials specifically purposed for custom laser laminations, Fred R. Rippy, Inc. upholds the apex of quality standards. For further inquiries on our avant-garde CO2 laser offerings or custom laser laminations, we invite you to contact Fred R. Rippy, Inc. today.