stamping capabilities

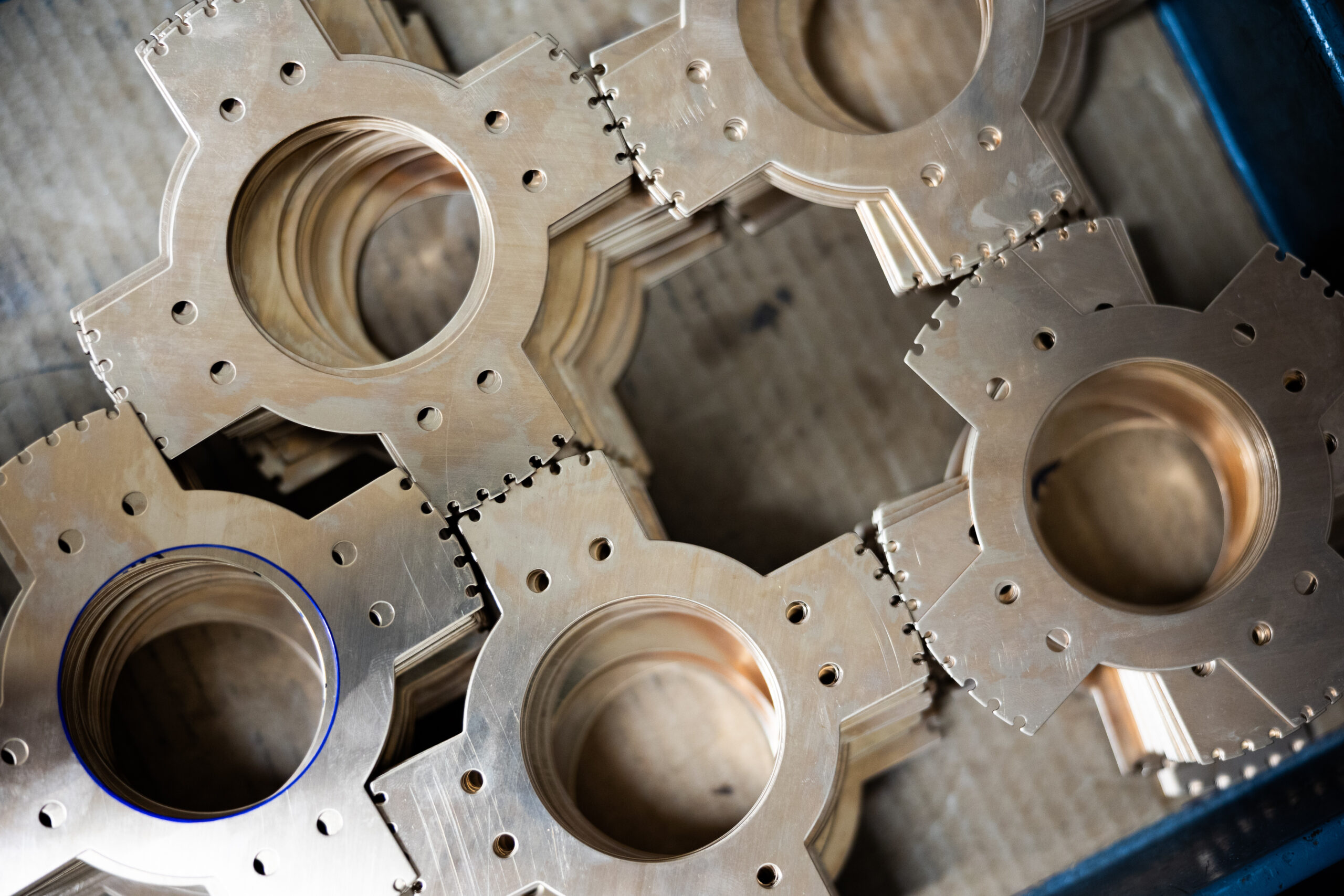

We typically stamp laminations up to 10” diameter but we have done over 30” diameter parts using special tooling. Rippy has stamped parts as thin as 0.004” and up to 0.062” thick. Regarding raw material, we stock standard silicon steels (typically with a C4 or C5 coating), most alloys (high nickel, high cobalt, and copper) up to 0.032” thick. We also carry the common insulating materials such as Nomex, Mylar, and G-series up to 0.032” thick.

Questions about our process? Contact us today.